- 0222817233

- 0222817234

- marketing@northcairomills.com

North Cairo Mills Company

Modern grinding technology is used

The company has a milling capacity (72% + 82%)

With a total of 2800 tons / day

Distributed over 12 production units

The company has 12 production units

To produce all kinds of flour

Some of the company's production units

Al Huda Mill, Al Sharabia Mill

Al Kawthar Mill, Al Safa and Al Marwa Mills

Al Huda Mill Italian Singati

With a capacity of 600 tons / day

fooad Flour Mill (Buhler)

With a capacity of 200 tons per day

Company implementation

Buhler Swiss

The company has storage capacity of silos

And the banks reach to 20100 thousand tons

Metal silos

The 10th of Ramadan silo

Storage capacity of 60 thousand tons

The company has storage capacity of silos

And the banks reach to 20100 thousand tons

Banker Tenth of Ramadan

Storage capacity of 70 thousand tons

The company has storage capacity of silos

And the banks reach to 20100 thousand tons

Metal silos

Mostorod silos

Storage capacity of 30 thousand tons

Some of the company's products

Flour extract 72% and Germina wheat germ

Mix cake with all kinds

Basbousa

Pudding all kinds, to the top of the judge

North Cairo Mills Company

Modern grinding technology is used

Watch the company profile

Film material shown

Quality policy

- The senior management in North Cairo Mills Company sets the standard for excellence as a target for it. In order to achieve this, specific strategies are adopted for all areas of the company’s work, whether in production sites or in service sites, and until quality in its comprehensive concept comes at the top of the concerns of all those responsible for implementing the company's policy that is also mandated between All who work with them.

• The quality policy adopted and adhered to by the company, which aims to achieve the highest levels of quality in its products and aims to satisfy the requirements and needs of its customers in the present and meet their desires and expectations in the future.

The senior management in North Cairo Mills Company sets the standard for excellence as a target for it. In order to achieve this, specific strategies are adopted for all areas of the company’s work, whether in production sites or service sites, and until quality in its comprehensive concept comes at the top of the concerns of all those responsible for implementing the company’s policy that is also mandated between All who work with them.

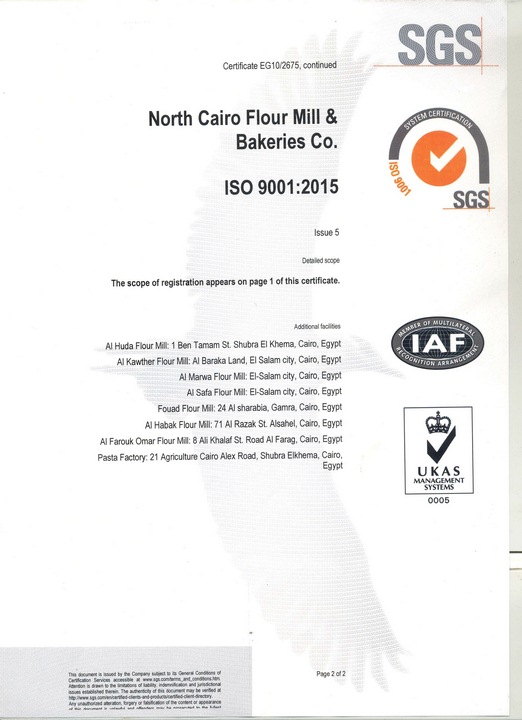

In implementation of this policy, the company is committed to applying an effective and documented quality assurance system that meets the requirements of international standard ISO 9001 and is committed to every individual of the company and makes all employees convinced and committed to implementing the quality assurance system and maintaining its success, continuity and development regularly.

Quality of wheat -

The quality of wheat is monitored from the beginning of reception until its storage, mixing, cleanliness, and then moistening, in order to ensure its consistency and appropriateness for milling, and many experiments are conducted on it in order to ensure its quality (detection of specific weight - moisture - protein - fall number - impurities).

The quality of flour -

There are many tests that we perform to check the quality of the flour, such as ash - moisture - protein - pH number - enzymatic activity - persistence and absorption rate, according to Egyptian standard 1251 for the year 2005 issued in this regard.

Hazard Analysis and Identification of Critical Control Points H.A.C.C.P •

-

With the rapid and successive development in the field of food manufacturing worldwide and the consequent development of methods for controlling the quality of food products, a new system has been implemented to monitor the quality of food products through an integrated system starting from the raw materials involved in manufacturing processes and ending with the arrival of the final product to the consumer and called the This system "HACCP analysis and identification of critical control points" and this system allows, when applied, mills to determine what is called critical points, ie the places where the main hazards occur in the mill diagram and determine the sources of these hazards so that they can be avoided, and this system aims to Qiq ensure final product quality and ensure food safety or health of the final product.

0 0

0 0

- The senior management in North Cairo Mills Company sets the standard for excellence as a target for it. In order to achieve this, specific strategies are adopted for all areas of the company’s work, whether in production sites or in service sites, and until quality in its comprehensive concept comes at the top of the concerns of all those responsible for implementing the company's policy that is also mandated between All who work with them. • The quality policy adopted and adhered to by the company, which aims to achieve the highest levels of quality in its products and aims to satisfy the requirements and needs of its customers in the present and meet their desires and expectations in the future. The senior management in North Cairo Mills Company sets the standard for excellence as a target for it. In order to achieve this, specific strategies are adopted for all areas of the company’s work, whether in production sites or service sites, and until quality in its comprehensive concept comes at the top of the concerns of all those responsible for implementing the company’s policy that is also mandated between All who work with them. Quality of wheat - Hazard Analysis and Identification of Critical Control Points H.A.C.C.P •

|

|---|

Organizational Chart

Chairman of the Board of Directors Managing Director

Dr.Engineer/Ahmed El-Essawy Abdo Abdo

Ahmed Mohamed Ashmawi

Salama Sultan Mustafa

Social responsibility

Social and environmental responsibility is a priority

The company takes into account to maximize its added value to the company and society Subject to human rights

Labor standards and environmental protection

As well as encouraging the development of technology that is not harmful to the environment at work

Guiding sites

Ministry of Supply and Internal Trade

Food Industries Holding Company

Sugar and integrative industries

Egyptian starch and yeast industry

Nile for detergents and oils

South Cairo and Giza Mill

Alexandria Mills

Middle Egypt Mills

contact us

North Cairo Mills and Bakeries Company

Address: El-Salam City - Cairo - Egypt

Phone: 22817234 - (202+) 228172330

Fax: (+202) 22817234 - (228) 228172330

Email: marketing@NorthCairoMills.com

Website : www.northcairomills.com